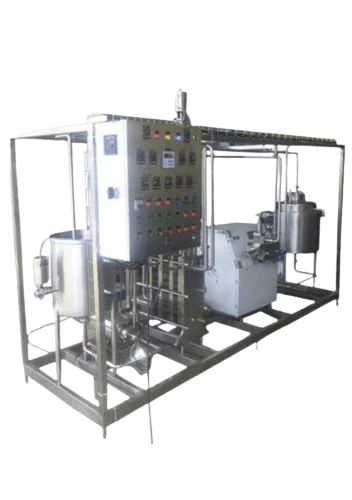

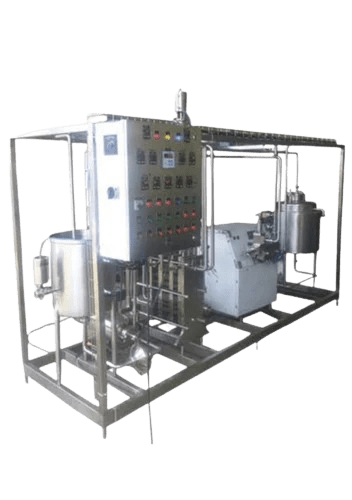

Milk Processing Plant Manufacturer

Are you looking for a Milk Processing Plant Manufacturer in India? Look no further than 99 Business Vyapar. As a leading milk processing plant manufacturer and supplier, we specialize in providing top-notch solutions for your dairy processing needs. Our extensive network ensures that you find the right milk processing plant factory to meet your requirements. We offer competitive milk processing plant costs in India, providing transparent pricing and exceptional value. Whether you’re interested in understanding the milk processing plant price or exploring different options, 99 Business Vyapar is your trusted partner in securing a high-quality milk processing plant tailored to your business needs.

What is a Milk Processing Plant?

A milk processing plant is a specialized facility designed to process raw milk into various dairy products, ensuring quality, safety, and efficiency. These plants are equipped with state-of-the-art technology to handle every stage of milk processing, from pasteurization to packaging.

Milk Processing Plant Feature:

Advanced Filtration Systems: Ensure the removal of impurities and contaminants from raw milk, providing a clean and pure product.

Pasteurization Equipment: Utilizes precise heating techniques to eliminate harmful bacteria and pathogens, making the milk safe for consumption.

Homogenizers: Break down fat molecules to prevent cream separation and ensure a smooth, consistent texture in dairy products.

Cooling Systems: Maintain optimal temperatures for preserving the freshness and extending the shelf life of milk and dairy products.

Automated Filling and Packaging Lines: Streamline the bottling and packaging process to enhance efficiency, accuracy, and hygiene.

Quality Control Laboratories: Conduct rigorous testing and analysis to ensure that all products meet safety standards and quality requirements.

Storage Facilities: Include refrigerated tanks and silos for proper milk storage, preventing spoilage and maintaining quality.

Waste Management Systems: Manage by-products and waste materials effectively, contributing to environmental sustainability.

Energy Efficiency: Incorporate energy-saving technologies to reduce operational costs and minimize environmental impact.

Integrated Control Systems: Offer real-time monitoring and management of the processing line for optimal performance and reduced downtime.

Advantages of a Milk Processing Plant

Enhanced Product Quality: Achieve consistent taste, texture, and safety in dairy products through advanced processing techniques.

Improved Safety and Hygiene: Ensure the highest safety standards with thorough pasteurization and rigorous hygiene practices.

Increased Shelf Life: Extend the freshness of milk and dairy products with effective cooling and packaging technologies.

Efficient Production: Streamline operations with automation, reducing labor costs and increasing overall production efficiency.

Product Diversification: Produce a variety of dairy products, including cheese, yogurt, butter, and ice cream, to meet diverse consumer needs.

Economic Benefits: Optimize production processes to reduce waste, lower costs, and boost profitability.

Environmental Sustainability: Minimize environmental impact with advanced waste management and energy-efficient technologies.

Regulatory Compliance: Meet industry regulations and standards through rigorous quality control measures, fostering consumer trust.

Enhanced Supply Chain Efficiency: Improve supply chain management with integrated control systems, ensuring timely product delivery.

Support for Dairy Farmers: Provide a reliable market for milk and support local dairy farmers by processing their raw milk efficiently.

Minimum Order Quantity | 1 Unit |

Capacity | 100Lph to 5KLPH |

Equipment Type | Paneer Coagulation Tank, Milk Chillers, Milk Storage Tanks, Milk Pasteurizer, Homogenizer |

Application | Milk |

Design Type | Customized, Standard |

Machine Body Material | SS 304 |

Automation Grade | Automatic |

Electric Power | 2kw to 80kw |